In the chemical industry, safety and reliability are critical. The oil-free design of Upheat heat pumps minimizes the risk of oil leaks, ensuring a clean and stable heat source. High energy efficiency leads to significant savings, and renewable energy compatibility boosts sustainability.

With a quick ROI and lower total ownership costs, Upheat heat pumps help chemical manufacturers reduce emissions, improve energy efficiency, and maintain safety standards. For those focused on heating, we offer a Heat-as-a-Service package where you only pay for the results.

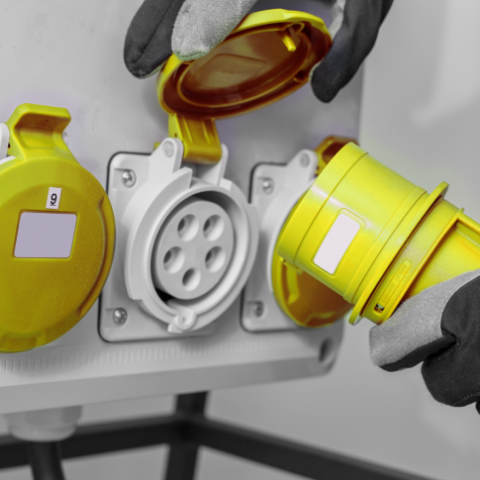

The Upheat heat pump is a containerized, modular solution for easy integration. Connect it to your waste heat source, electrical power, and heat sink for a quick setup with minimal downtime. Experience a fast and hassle-free installation!

Scenario: A chemical plant in Finland requires 1 MW of heat for a distillation process.

Heat Output / COP = 1 MW / 2.8 = 0.36 MW

0.36 MW × 8,000 hours/year × 95€/MWh = 269,269 € per year

Maintenance Cost

10,000 € per year

Cost of CO2

0 € per year

279,269 € per year

1 MW × 8,000 hours/year = 8,000 MWh/year

1 MW × 8,000 MWh × 95€/MWh = 760,000 € per year

Maintenance Cost

10,000 € per year

Cost of CO2

439,200 € per year

1,209,200 € per year

Payback: ~1 year