The Upheat high-temperature heat pumps replace fossil fuels with efficient, electric heat in the 100°C to 200°C range that these processes require. Our pumps capture waste heat and transform it back to usable temperatures. They utilize natural refrigerants that are environmentally friendly, helping companies align with net-zero goals. By minimizing reliance on fossil fuels, Upheat significantly reduces emissions while maintaining product quality and safety.

With The Upheat high-temperature heat pumps, pulp, paper, and wood processors can substantially lower their energy costs. Our technology delivers up to 7 times more heat energy per unit of electricity consumed, resulting in significant operational savings. The oil-free design reduces maintenance needs and downtime, ensuring long-term reliability in high-demand production environments.

Companies typically see a return on investment (ROI) within 1 to 3 years, providing financial advantages that help meet decarbonization targets without compromising performance. For those focused solely on heating, we offer a Heat-as-a-Service package, allowing you to pay only for the results.

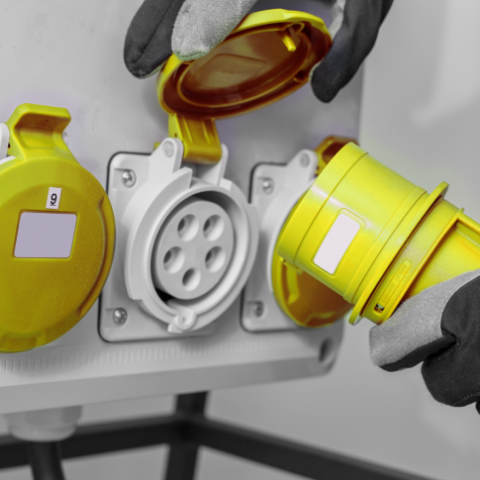

The Upheat heat pump is a containerized, modular solution for easy integration. Simply connect it to your waste heat source, electrical power, and heat sink for a quick setup with minimal downtime. Experience a fast and hassle-free installation!

A paper mill in Austria requires 1 MW of heat for a specific part of the drying processes.

Heat Output / COP = 1 MW / 3.0 = 0.33 MW

0.30 MW × 8,000 hours/year × 255€/MWh = 679,119 € per year

Maintenance Cost

10,000 € per year

Cost of CO2

0 € per year

€689,119 per year

1 MW × 8,000 hours/year = 8,000 MWh/year

1 MW × 8,000 MWh × 72€/MWh = 576,000 € per year

Maintenance Cost

10,000 € per year

Cost of CO2

439,200 € per year

€1,025,200 per year

Payback: 3 years