The Upheat oil-free high-temperature heat pumps are designed to help industries move away from fossil fuels for process heat above 100°C. Optimized for heat sink temperatures between 100°C and 200°C and capable of achieving temperature lifts between 68 and 110°C, our heat pumps excel in demanding industrial environments.

By removing oil-lubricated compressors, bearings and gears, we offer a solution that enhances efficiency, reduces maintenance needs, maintains refrigerant purity and minimizes environmental impact. Removing oil from the compressor simplifies the system and lowers service needs. The compressor uses high-speed motor technology and direct drive turbo compression levitating on Active Magnetic Bearings (AMB), so the rotor only touches the refrigerant and, therefore, is exposed to no other friction. Also the heat exchanger surfaces remain clean. This means that the refrigerant compressor is more efficient and practically maintenance-free and can operate in a wide range of efficient operating points based on different production needs.

Our advanced technology utilizes natural refrigerants and high-speed turbo compressors, enabling exceptional energy efficiency and significant CO₂ reduction. With the capability to deliver 3 to 7 times more heat energy than the electrical energy consumed, Upheat heat pumps provide a reliable and cost-effective option for industrial decarbonization. Our heat pump is ready for the future, using environmentally friendly natural refrigerants, ready for FGAS and PFAS regulations. Future-proof for decades to come.

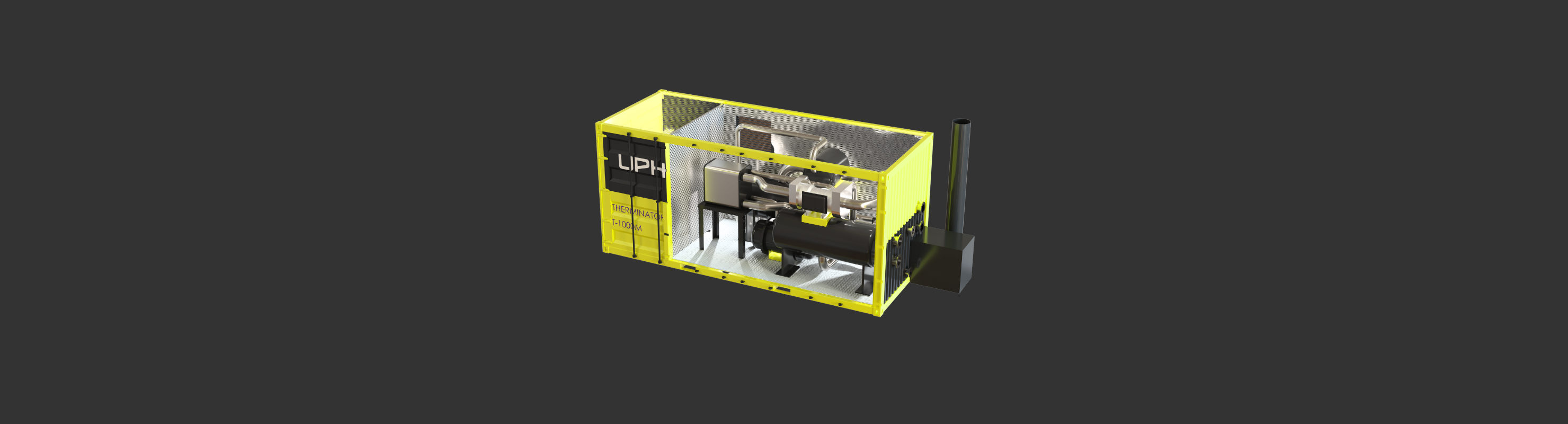

The Upheat solution is a plug-and-play system designed for easy implementation and flexibility to meet diverse heating needs. Featuring a containerized, modular design, it integrates smoothly into existing systems with minimal disruption. Connect it to your waste heat source, electrical power, and high-temperature piping for a quick setup and installation with minimal downtime.

Whether installing new systems or retrofitting existing ones, Upheat provides comprehensive support during installation and operation. Our heat pumps can replace your current heat generation, effectively capturing waste heat and delivering it back to production at the desired temperature.

| Therminator T-1000M | Therminator T-2000M | Therminator T-1000L | Therminator T-1000H | |

|---|---|---|---|---|

| Output medium | Steam/water | Steam/water | Steam/water | Steam/water |

| Heating power | 700-1600 kW | 1400-3200 kW | 700-1600 kW | 800-1300 kW |

| Nominal input temperature | 40-60 °C | 40-60 °C | 30-50 °C | 60-80 °C |

| Temperature lift change | 68…105 °C | 68…105 °C | 68…105 °C | 84…110 °C |

| COP at minimum temperature lift | 4,0 @ 68 °C lift | 4,1 @ 68 °C lift | 4,0 @ 68 °C lift | 3,6 @ 84 °C lift |

| COP at maximum temperature lift | 2,8 @ 105 °C lift | 2,9 @ 105 °C lift | 2,8 @ 105 °C lift | 3,0 @ 110 °C lift |

| Output temperature | 108-165 °C | 108-165 °C | 98-155 °C | 144…190 °C |

| Motor power | 400 kW | 800 kW | 400 kW | 400 kW |

| Availability | 2026 | 2027 (estimated) | 2027 (estimated) | 2028 (estimated) |